IC ENGINE - BASIC TERMS AND DEFINITION

INTERNAL COMBUSTION ENGINE

An internal combustion engine is one in which the fuel is burnt within the

engine. It is usually of the reciprocating type. Combustion of the fuel and the conversion of the heat energy from combustion to mechanical energy takes place within the cylinders. Ex. Petrol engine, Diesel engine

EXTERNAL COMBUSTION ENGINE

If the combustion of fuel place outside the engine cylinder, it is an external combustion engine. Ex: Steam turbine, Gas Turbine, Steam Turbine etc.

BASIC TERMS AND DEFINITION

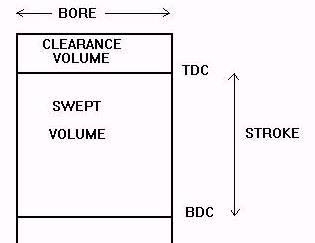

1. SWEPT VOLUME -: This term refers to the volume swept by the piston during one stroke and is the product of the piston area and stroke.

2. CLEARANCE VOLUME-: It is the volume remaining in the cylinder when the piston is in the top-centre position. The difference between the total cylinder volume and the swept volume is equal to the clearance volume.

3. COMPRESSION RATIO-: This is the value obtained from dividing the total cylinder volume by the clearance volume and will be from 12 to 18, depending on the engine design.

OR

Ratio of the volume of air at the start of the compression stroke to

the volume of air at the end of this stroke

4. VOLUMETRIC EFFICIENCY -:This is the ratio of the volume of air drawn into the cylinder (at normal temperature and pressure) to the swept volume. In naturally aspirated four-stroke engines the volumetric efficiency will be from 0.85 to 0.95.

5. SCAVENGE EFFICIENCY-: This is the ratio of the volume of air (at normal temperature and pressure) contained in the cylinder at the start of compression to the volume swept by the piston from the top edge of the ports to the top of its stroke.

6. AIR CHARGE RATIO-: This is the ratio of the volume of air (at normal temperature and pressure) contained in the cylinder at the start of compression to the swept volume of the piston.

This term has now more or less replaced the previous two terms :

It is sometimes referred to as air mass ratio or air supply ratio.

7. NATURAL ASPIRATION-: It is a term applied to four-stroke engines where the air charge is brought into the cylinder only by the downward movement of the piston without other aids.

8. SUPERCHARGING-: It is a term used to indicate that the weight of air supplied to the engine has been considerably increased. This allows more fuel to be used per stroke with a consequent increase in engine output power.

9. MECHANICAL EFFICIENCY-: A measure of the mechanical perfection of an engine. Numerically expressed as the ratio between brake Power and indicated power.

10. SPECIFIC FUEL CONSUMPTION-: Fuel consumption per unit energy at the cylinder or output shaft, kg/kWh (or kg/kWs), 0·19 kg/kWh would be normal on a shaft energy basis for a modern engine.

11. INDICATED HORSE POWER (IHP) -: Power produced on the cylinder because of the expansion of gas is called Indicated Horse Power.Hence it forms the basis of evaluation of combustion efficiency or the heat release in the cylinder. It is calculated based on the design of the engine using a theoretical formula:

IHP = PxLxAx(N/60)

P = Mean indicated pressure of the cylinder

L= stroke length

A= Bore area of cylinder

N= engine rpm

12. BRAKE HORSE POWER(BHP) -: It is the power available at the crankshaft of the engine. It is calculated using a brake dynamometer and hence called brake power. It is less than IHP due to pumping, inertia losses and friction losses.

BHP = IHP – (Pumping loss + inertia loss + friction loss within engine)

13. SHAFT HORSE POWER (SHP)-: It is the power available at the propeller shaft for rotating the propeller. It is lesser than Brake power by the amount of power lost in transmission

SHP = BHP – Transmission losses

14. MAXIMUM CONTINUOUS RATING (MCR)-: The maximum output that can be produced by an engine continuously without causing failure to the propulsion machinery.

15. NOMINAL CONTINUOUS RATING (NCR)-: It is usually 85-90% of MCR. It is the contractual output for which the propeller is normally designed. The continuous service rating is the power at which the engine is normally assumed to operate.

14. MEAN EFFECTIVE PRESSURE -: The mean effective pressure (MEP) is the average pressure during the power stroke, minus the average pressure during the other three strokes.

15. BORE -: The diameter of the cylinder is known as bore.

16. STROKE-: The displacement of the piston, i.e. its travel from

top dead centre (TDC) to bottom dead centre (BDC) is called stroke.

Comments

Post a Comment

Open for Suggestions and Corrections