BASIC THERMODYNAMIC CYCLE - OTTO CYCLE , DIESEL CYCLE

Thermodynamic cycle is either to produce power, or to produce

refrigeration/pumping of heat. Therefore, the cycles are broadly classified as follows:

(a) Heat engine or power cycles.

(b) Heat pump cycles or refrigeration cycle.

The power cycles are accordingly classified into two groups as:

(1) Vapour power cycles in which the working fluid undergoes a phase change during the cyclic process. Ex- Steam Power Plant

(2) Gas power cycles in which the working fluid does not undergo any phase change.Ex- ICE

1. OTTO CYCLE

2. DIESEL CYCLE

AIR STANDARD ASSUMPTION FOR IDEAL CYCLE -:

> Gas and air mixture are considered as air and an ideal gas, which continuously circulates in a closed cycle.

> There are no intake and exhaust process.

> The processes are internally reversible.

> The combustion process is replaced by a heat-addition process from an external source.

> The exhaust process is replaced by a heat-rejection process and the gas returns to its initial state.

1. IDEAL OTTO CYCLE

a) Otto cycle is the ideal cycle for spark-ignition engines.

b) Otto cycle is executed in a closed system and the working fluid is air according to the air-standard assumption.

c) Otto cycle also called constant volume cycle as heat addition and rejection take place at constant volume.

WORKING -:

The working of the cycle can be understood by the PV and TS diagram.

The point 1 called as state point defining pressure and temperature of certain volume of air.

As no induction take place 0-1 shown dotted.

Process 1 - 2 : Isentropic Compression

Process 2 - 3 : Heat addition at Constant volume

Process 3 - 4 : Isentropic Expansion

Process 4 - 1 : Heat rejection at Constant volume

Same mass of air brought back to initial state 1.

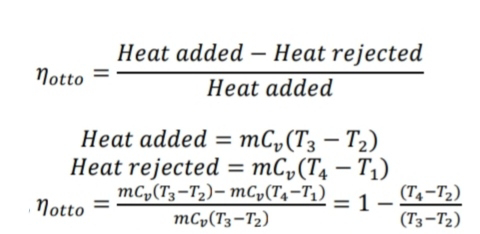

THERMAL EFFICIENCY -:

It is the ratio of Net workdone to the net heat input.

Net workdone = Heat added - Heat Rejected

Net heat Input = Heat added

Using Relationship for perfect gas law :-

therefore :

CONCLUSION -:

> The thermal efficiency depends on Compression ratio.

> Efficiency of otto cycle is function of Compression ratio and specific heat ratio.

> For particular gas special heat ratio is constant then efficiency will be directly proportional to Compression ratio.

ACTUAL OTTO CYCLE

Because -

> The compression is not adiabatic in actual and there is heat losses through the cylinder wall.

> In actual Combustion take place over a period of time during which the piston is moving away from TDC.

> In actual engine the suction/exhaust valve continue to open for some time and also continues to close for some time.

> There is some degrees of valve overlap designed to ensure proper scavenging of exhaust gases.

>There are blowdown losses due to early opening of the exhaust valves.

> Friction and leakage losses.

The actual cycle required four stroke in an engine that is :

1. SUCTION STROKE - Air charge drawn into the cylinder below atmospheric pressure suction valve closes at end of stroke.

2. COMPRESSION STROKE - With both Suction and Exhaust valve closed, the air is compressed by piston and few degree before the TDC spark ignition take place.

3. POWER / EXPANSION STROKE - After ignition the gas expand until at the end of stroke when the exhaust valve open.

4. EXHAUST STROKE - The remaining burned gass in the cylinder are forced out by displacement of piston extending over a full stroke.

2. IDEAL DIESEL CYCLE

a) Diesel cycle is the ideal cycle for compression-ignition engines.

b) In Diesel cycle heat addition take place at constant pressure.

c) Only air is compressed in combustion chamber and fuel injection is used.

WORKING -:

Process 1 - 2 : It is isentropic compression process

Process 2 - 3 : It is isobaric heat addition process during which the liquid fuel self- ignites at constant pressure

Process 3 - 4 : It is isentropic expansion process

Process 4 - 1 : It is a contant volume heat rejection process

Compression ratio: Ratio V1/V2 is known as compression ratio and is denoted by letter r.

Cut-off ratio: Ratio V3/V2 is known as cut-off ratio.

THERMAL EFFICIENCY -:

It is the ratio of Net workdone to the net heat input.

Net workdone = Heat added - Heat Rejected

Net heat Input = Heat added

CONCLUSION-:

>The bracket term is always greater than 1 . Hence thermal effeciency of diesel cycle always less then otto for the same Compression ratio.

> If the cutt off ratio increases, the bracketed term increases and efficiency decreases.

>Low fuel cutt off ratio is required for better thermal efficiency

> Diesel engine having Compression ratio range from 14-20 .

ACTUAL DIESEL CYCLE

Because-:

> In actual engines the heat addition is not isobaric.

> In actual cycle there is a pressure difference between exhaust and inlet pressure.

> In actual Combustion take place over a period of time during which the piston is moving away from TDC.

> In actual engine the suction/exhaust valve continue to open for some time and also continues to close for some time.

> Blowdown loss is caused by the early opening of exhaust valves. This results in a loss of work output during expansion stroke.

> The blow-by loss is caused by the leakage of compressed gases through piston rings.

> Friction losses in moving components.

COMPARISON BETWEEN OTTO & DIESEL CYCLE:

1. In Otto engines, due to spark ignition the maximum compression pressures are severly limited. In diesel cycles, the compression pressures are much higher as fuel needs to be injected in the combustion chamber after the compressed air has reached the self-ignition temperature.

2. Otto/petrol engines allow air fuel charge to be compressed, while diesel engines compress only the air charge while fuel is injected near TDC after the air charge has attained self-ignition temperature.

3. In Otto cycle, the heat addition is at contant volume, while in Diesel cycle the heat addition is at constant pressure.

DIFFERENCE BETWEEN OTTO CYCLE AND DIESEL CYCLE

Comments

Post a Comment

Open for Suggestions and Corrections